Overview

G-71 is a new, innovative, material for the protection of the kiln shelves from over melting glazes, with multiple additional benefits. It is very different from common non-stick products (alumina, kiln wash, kiln primer etc), as its special composition allows it to permanently maintain its elasticity. Common non-stick formulations - due to their composition - harden as soon as they are exposed at high temperatures and can not follow the contraction / expansion of kiln shelves during firing. This causes the coating to crack, and peels in a very short time. The pieces that come off float in the furnace, stick to ceramics and create defects. The application of a very thin layer of non-stick formulations significantly delays it cracking phenomenon, but does not offer any protection to the shelves. Applying non-stick powder, without mixing with water, overcomes the problem of the crack, but dust particles are suspended in the kiln during firing, and create defects in the ceramics, and often problems in the resistors, over to which they are finally attached.

Features

G-71 hardens after firing, but it retains its elasticity and follows the contractions /

expansions of the kiln shelves on which it is applied, it is integrated with the kiln shelves creating a dense, uniform coating, offering the following advantages:

It does not crack or peel.

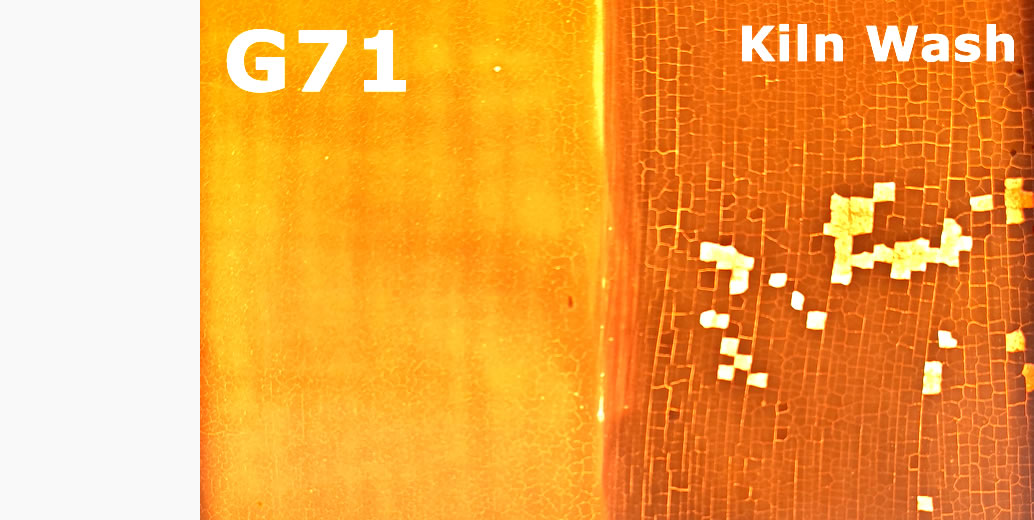

Kiln shelf in the example is coated half with G-71 and the other half with ordinary kiln wash.

It has been heated and photographed at 1280C (cone 9 / 2336F).

After 10 high temperature firings (1280C /cone 9 / 2336F), G71 remains uniform, without cracks.

On the contrary, the kiln wash has cracked from the first firing.

After 15 high temperature firings (1280C /cone 9 / 2336F), G71 remains uniform, without cracks.

Instead, kiln wash has already started to peel.

In this case, you have to clean the shelves, and re apply kiln wash.

It enhances uniform heat transfer through increased reflection

The shelf in the example is coated half with G-71 and the other half with kiln wash.

It has been heated and photographed at 1280C (cone 9 / 2336F).

The part of the shelf coated with G71 has a much higher reflection compared to the part coated with kiln wash.

Increased reflection enhances temperature uniformity, and energy savings.

It follows the contraction / expansion of the ceramics. As a result, even materials that are self glazed will not stick to it (such as porcelain, where parts of the base of the ceramic stick to the shelves) The objects in the example are glazed at their base. They were not cleaned, and were placed with the glazed surface in contact to the kiln shelf.

It is easily repaired, and does not require to completely clean the old coating to apply a new one.

In case that glaze over melts, and part of the coating comes off with the ceramics, just apply new material only at the point

where it came off.

The new material will bond with the old one and form an even layer.

Instructions

G71 contains only natural, mineral materials and does not carry a hazard mark. The use of gloves and a mask when applying the material is not necessary, but we recommend it. Application on new kiln shelves: We suggest that the new kiln shelves are first fired once, in order to remove the moisture they have and to burn any organic materilas. In this way we achieve better adhesion of the material to the kiln shelf. Application on old kiln shelves: In case the shelves have been painted with common non-stick products (alumina, kiln wash, kiln primer etc.) you must scrape them with a spatula to remove this layer. In case there are residues of glaze you should use a sander or wheel to remove the residues, so that you have a flat surface. Residues that are flush with the surface of the shelf do not need to be completely removed. Application instructions: 1. Shake the bottle very well to mix the material 2. Clean kiln shelves from dust 3. Wipe the shelves with a damp sponge 4. Use a good quality brush, to get an even smooth surface. 4. Apply the first coat of G71. We suggest the first layer to be made with material diluted by 20% with water. First layer must penetrate into the pores of the shelf. Apply while pressing the brush, to get better results. The first application leaves a thin layer of material on the surface of the shelf, and it does not have much coverage, the color of the shelf will still be visible. Allow to dry very well, before applying more layers. Apply 2 more thick layers with undiluted material or diluted by 10% with water. The second and third layer must be applied thick. Do not just “paint” the shelves, the layer must remain thick. It is very important to allow each coat to dry well before applying the next. These 3 layers will protect kiln shelves from most common accidents. You can use the kiln shelves with the fresh coating immediately. There is no need to fire the coated kiln shelves before using them as usual. Depending on the protection level you want, you can apply extra layers. In our extreme in house testing, where we overfired a low temperature clay body, so it completely melted, we used 8 thick layers of G71. Top layer did some small cracks during firing, but the melted ceramic did not stick to the shelf. Applying normal quantity of G71 will not pluck, nor crack. You can also cover the edges of the shelves, so that any melted material will not stick there either. You can also apply the material locally, over previous layers, on parts of the shelf where you will place objects that may cause you problems. Upon completion of the process, clean your tools with clean water. Close the bottle tightly with any leftover material for future use, and store it in a cool place so that it does not evaporate. In the next use, you can add extra water to achieve the desired density. Applying new layers: In case of cracking, apply a new layer of material over the cracked one without the need to remove the old layer. You can apply a new layer of material, over the previous ones, in case the old layers have started to lose their thickness, or in case you want additional protection. It is not necessary to clean the shelves, scrape off old material before applying a new layer. In case that glaze over melts, and part of the coating comes off with it, apply with a brush material only at the point where it came off.